HOME

ATW Manufacturing Company, Inc.

800 759-3388, 541 484-2111 M-F, 8-5, Pacific Time

![]() Manufacturing

Co., Inc. (541) 484-2111 email

Manufacturing

Co., Inc. (541) 484-2111 email

Master Sealer Distributor for 25 years!

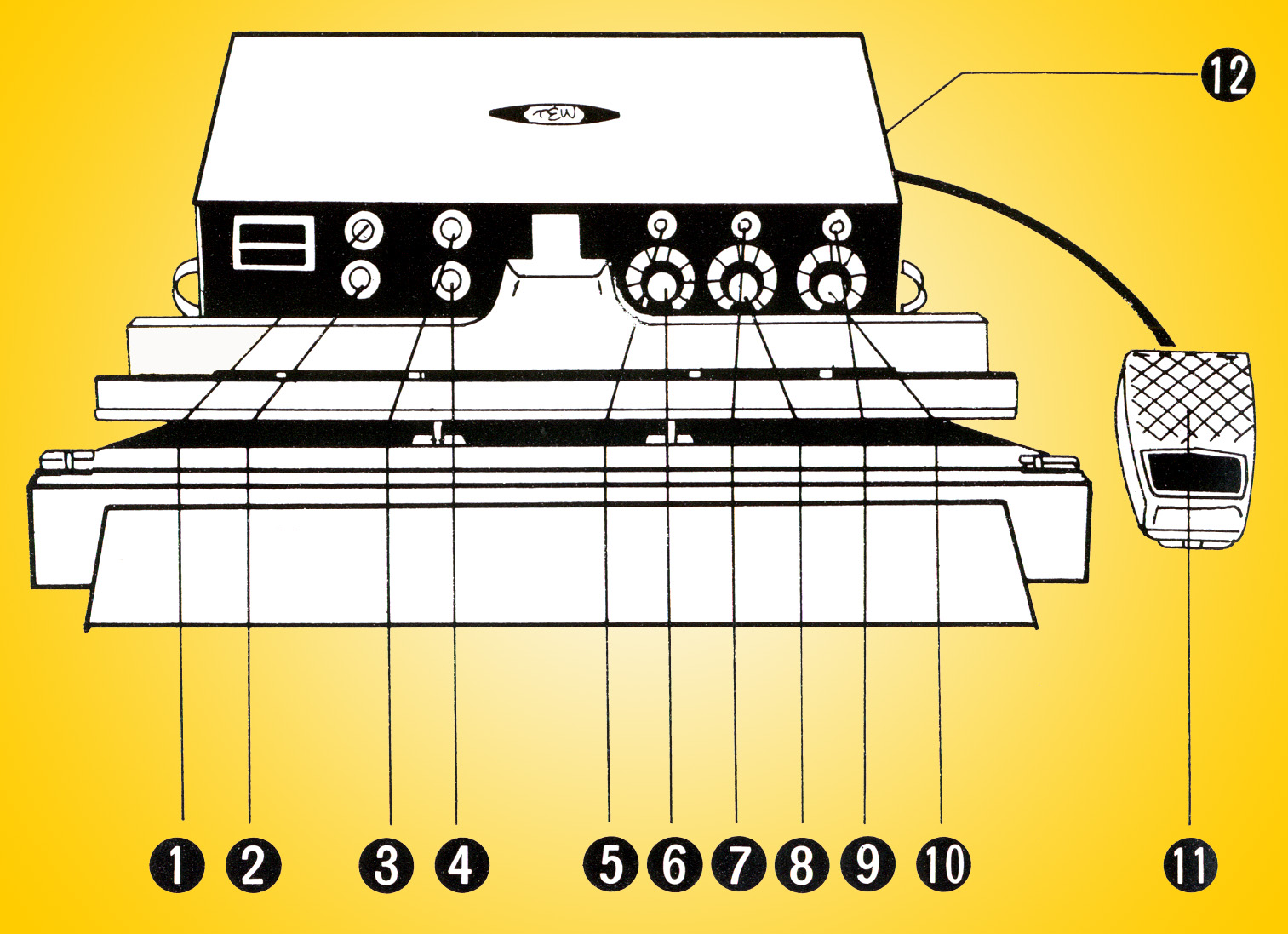

TEW / AIE Automatic Impulse Sealers

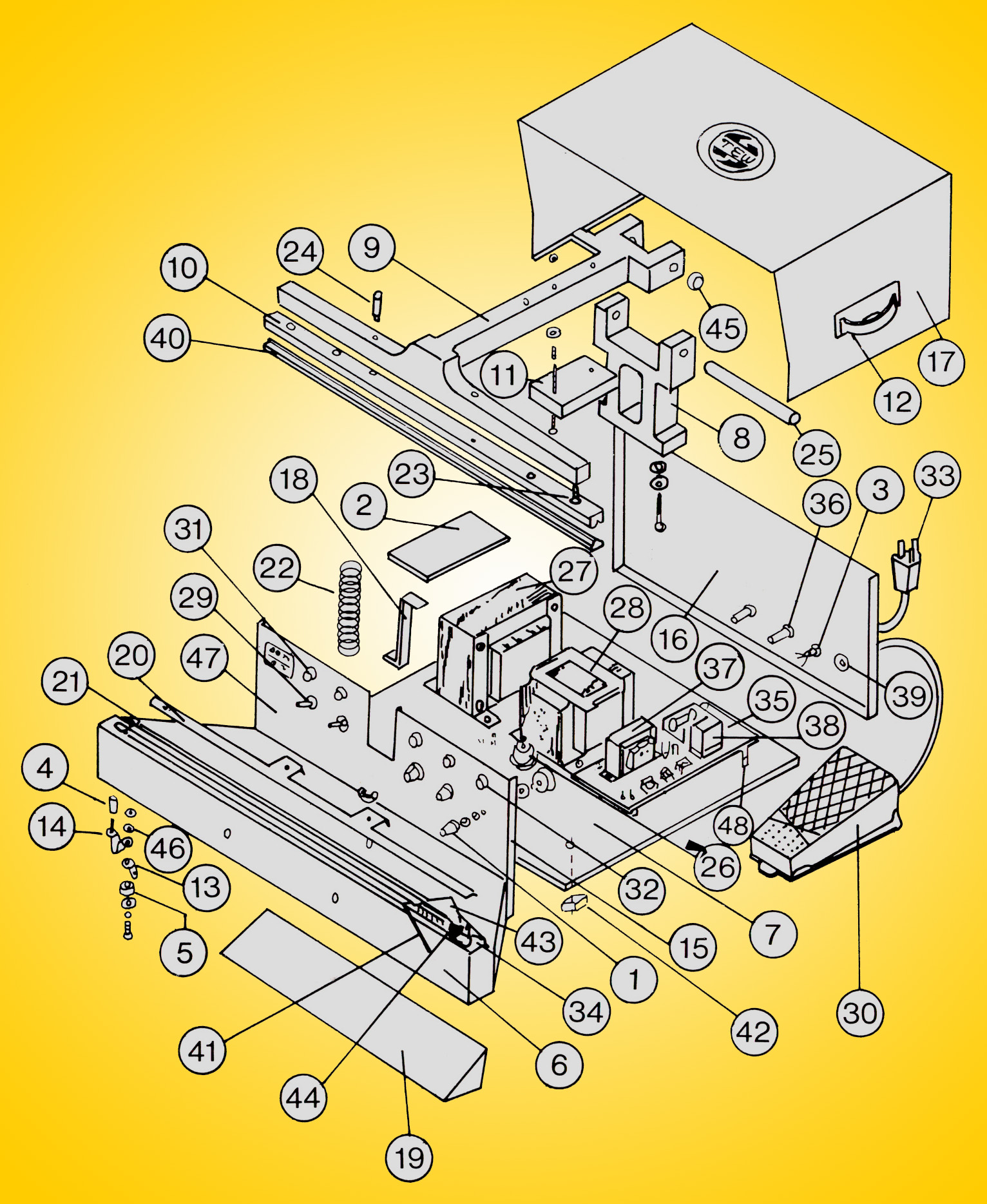

OPERATING

INSTRUCTIONS, PARTS LIST, SCHEMATIC DIAGRAM

For Model Numbers TISA-452, 602, 455, 605 & AIE MODELS

AIE-300A1, 305A1, 450A1, 455A1, 600A1, 605A1

14",

18" AND 24" MODELS

THIS PRODUCT

WAS DESIGNED FOR CONVENIENCE

AND PERFORMANCE.

PLEASE READ THE FOLLOWING INFORMATION

BEFOR USE.

ADDITIONAL

INFORMATION

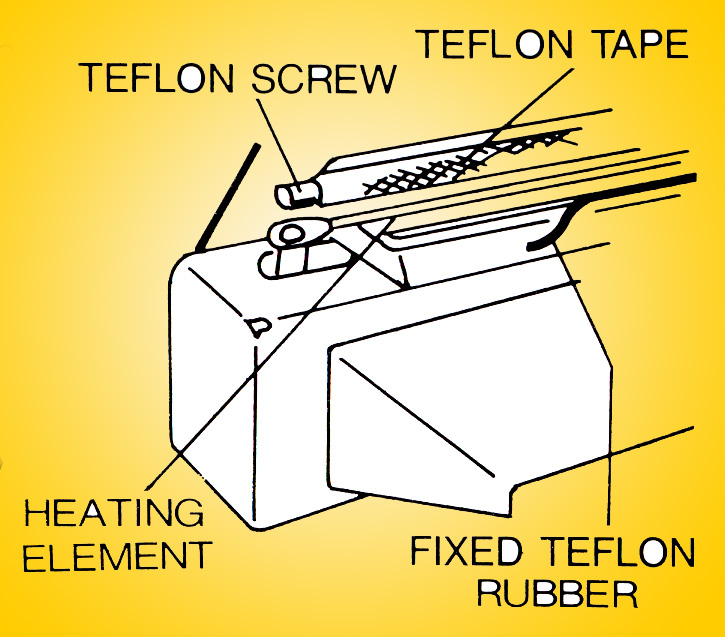

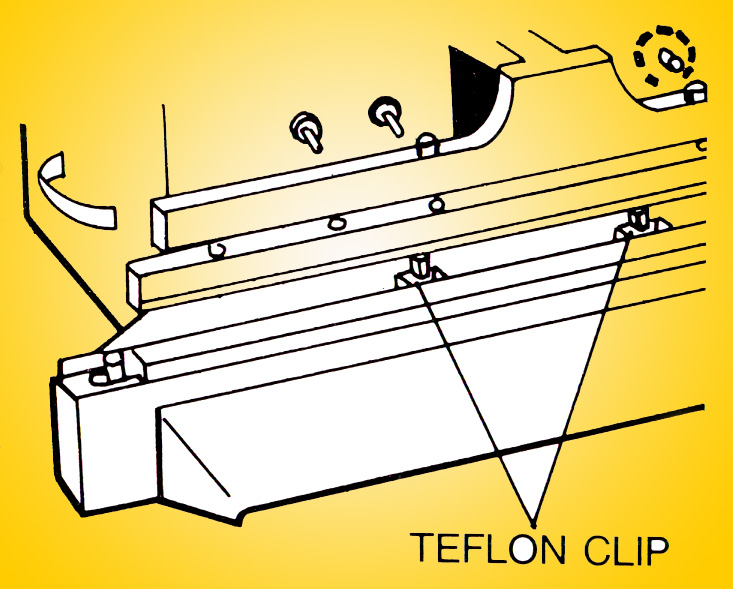

Always keep the sealing platform clean. Particular care should be taken to remove any melted plastic residue from the PTFE non-stick fabric scroll. Do not clean the sealing platform with anything wet. If the bottom non-stick PTFE Heat Tape, (under the heating element) becomes worn, the heating element may short, and this will damage the element wire. After a long

period of extensive use the condition of the white

silicone rubber top pressure pad should be

examined for wear. Obviously

any deformation will affect the quality of the

seal. The white silicone pressure pad is easily

replaced. We have them in stock. |

|||||||||

|

Spare Heating Element Wires, PTFE Tapes and Cloth/Fabrics, as well as

a HUGE inventory of poly bags and tubing, cellophane bags and shrink wrap, shrink bands and shrink tubing.

Phone: 800 759-3388 - 541 484-2111• FAX: 541 484-1493 or email

TEW

/ AIE Factory Authorized Service. We stock parts for TEW,

AIE, Midwest Pacific, Sealmaster, KF and nearly every brand of

sealer! USA made repair Kits, Non-Stick PTFE Heat Tapes and Cloth or

Fabric, Heating Elements, as well as a HUGE inventory of

poly bags, cello bags and vacuum pouches.

For complete current or special

pricing, call 800-759-3388, 541

484-2111 or email

HOME |

ABOUT

US | CONTACT US

| GENERAL

INFORMATION

© 2002 - 2023 ATW Manufacturing Company, Inc.