|

HOME

Manufacturing

Company's

Vacuum

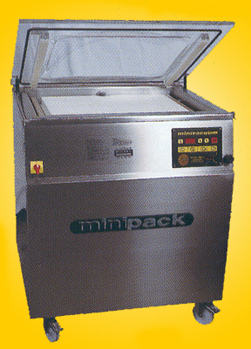

Packaging Chamber Machines Manufacturing

Company's

Vacuum

Packaging Chamber Machines

ATW

Manufacturing recommends that when your vacuum

packaging needs exceed 75 packages a week, it is

time to consider a vacuum chamber instead of a

non-chamber (or front nozzle type) vacuum

packaging machine. Why?

1. Chamber machines are faster. Bigger

and better vacuum pumps make for faster

packaging at higher levels of vacuum.

2. BIG cost savings! Vacuum

Chamber machines use standard, inexpensive

vacuum pouches and boilable pouches instead of

the expensive vacuum bags or micro layered type

pouches required on non-chamber machines.

3. How much money will you save?

As an example, consider the cost difference of

an 8" by 10" vacuum pouch for a chamber machine

and an 8" by 10" micro pouch for a non-chamber

machine. By using a vacuum chamber machine with

ATW's regular vacuum pouch, you'll save 11¢ on

each package! Vacuum bags for non chamber

machines typically cost 3 times more than standard

vacuum pouches!

All of our chamber machines use the highest

quality, BUSCH

vacuum pumps from Germany and

motorola

pressure switches for

fast and accurate chamber

evacuation...perfect every time. Very easy

to use. motorola

pressure switches for

fast and accurate chamber

evacuation...perfect every time. Very easy

to use.

Each vacuum chamber comes with programmable

digital controls with 9 user selectable

programs and cycle counters to accommodate

any vacuum packaging needs you have!

Plus,

each vacuum chamber machine has a Stop Cycle

switch; necessary for vacuum packaging

liquids, and a Soft Air Diffuser for packaging

fragile products.

The Seal bars have a 4mm

sealing wire (approximately 1/4" finished seal

size) PLUS a bag/pouch trim wire.

The Sealing bars are the "Quick Pull Out" type

for easy maintenance and quick chamber

cleaning.

Most important, on the models with multiple

sealing bars, each seal bar is powered

independently using a dedicated transformer.

In the unlikely event that that one

transformer malfunctions, only that sealing

bar is out. Your production keeps going until

you find some down time to have the

transformer repaired.

ATW's vacuum chambers are constructed of

heavy-duty stainless steel including

the frame. All the electronic components

areprotected in a moisture resistant case for

long life. Please allow 5 to 7 days lead time

for shipping. FOB Orange CA.

ALL OUR VACUUM SEALERS

ARE BRAND NEW...NEVER REFURBISHED.

YOUR SATISFACTION IS

GUARANTEED!

For the retail deli, the commercial

kitchen, the coffee roaster, the packing plant,

even medical or emergency supply makers, we have

the vacuum machine you need. We have all the

vacuum pouches too!~ Give us a call! 800

759-3388

1 Seal Bar

12-1/4" Across the Front

4mm seal with pouch trimmer

Vacuum Chamber

4-1/4" High

12-3/4" Wide

11-3/4" Front to Back

1/4 hp Pump

115 Volt @ 9A

Overall Size 15"x 20"x 12"h

*Estimated Ship Wt. 130lbs

STANDARD FEATURES: Includes Digital

Control with up to 9 Programs

Electronic Pressure sensor • Removable

Sealing Bar for easy cleaning •

Stainless Steel Construction

Stop Cycle Switch

YOU CAN'T BEAT THIS PRICE FOR A HIGH

QUALITY VACUUM CHAMBER MACHINE WITH ALL

THESE FEATURES!

|

3 Seal bar

2@12-1/4"

OnSides

1@20-1/4" Across Front

Vacuum Chamber

6 " High

24" Wide

13" Front to Back

1 hp Busch Pump

115 Volt @ 11A

Overall Size 28"w x 20"d x 26"h

*Estimated Ship Wt. 275lbs

Standard Features Same as listed at left

under Model MVS 31

The MVS 42 ADDS 1-3/4" TO THE CHAMBER

HEIGHT, AND A LARGER (1 H.P.) Busch

Vacuum Pump

|

Big Time Performance in a Table-Top Vacuum

Packing Machine! Super Easy to Use!

1 Seal Bar

17-3/4"

long across the front.

The 18" x 18" x 9" h Chamber is

perfect for vacuum packing multiple

pouches or vacuum bags at once. Just lay

them inside the chamber, push the

"start" button.

1 H.P.

Busch Vacuum Pump!

Large Vacuum Chamber (both models)

9" High

18" Wide

18" Front to Back

*115 Volt @ 18 Amps

Overall Size 21.5"x 24"x 14.5"h

*Estimated Ship Wt. 220lbs

STANDARD FEATURES: 9 Program Digital

Controller, Electronic Pressure Sensor,

Removable Sealing Bars for easy

cleaning, Stainless Steel Construction,

Safety Stop Cycle Switch

Options: Inert Gas Kit

Slant Tray for Liquids

|

|

|

|

Two Sealing Bars, 19-3/4" Long Two Sealing Bars, 19-3/4" Long

Left and

Right sides

22" BETWEEN SEAL BARS!

Vacuum Chamber

8-3/4 " High

26" Wide

20-1/4" Front to Back

3 hp Pump

208 Volt/3ph @ 6 Amps Overall Size 30"x 28"x

55"h / Shipping

Wt. 495lbs

208v/3phase/3

H.P. PUMP

220v/1phase/2 H.P. PUMP

Options:

Inert

Gas Kit

Third Sealing Bar Across the Front (25-1/2"

Long)

|

5 H.P. Busch Vacuum PUMP!

NO MACHINE ON THE MARKET

CAN MATCH ITS 25.75" DUAL SEALING BARS

WITH 24" BETWEEN THE BARS!

Vacuum Chamber

10" High

28.5 " wide

28.5 " front to back

208 Volt/3ph @ 16A

Overall Size

34 "x 32"x 55"h *Estimated Ship Wt.

628lbs.

Options:

Gas Flush Kit / Slant Tray for

liquids /

11-1/2"

Chamber height

|

2,3, or 5 H.P. Busch Vacuum

Pumps!

What kind of speed do you need?

|

All our Vacuum Chamber Machines can be custom

ordered with any seal bar configuration you need.

Just call us! GET INTO PRODUCTION NOW! IT'S EASY!

All vacuum chambers are FOB Orange, CA.

800 759-3388 or email

to sales@atwmfg.com

|

|

|

| |

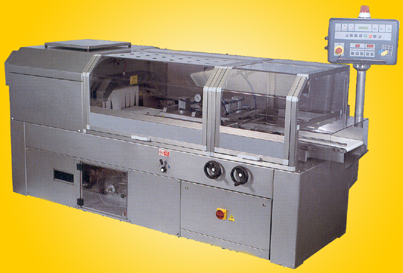

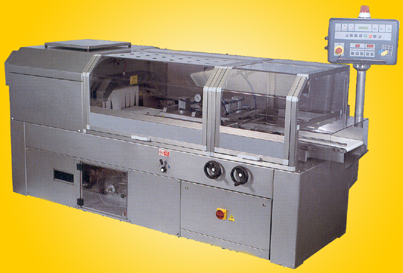

Modified Atmosphere

Packaging

System (MAP)

The system is ideally suited for

packaging a wide range of fresh foods such as meat,

sausage, cheese, pasta, frozen fish and many other

food products. The machine creates a hermetically

sealed, leak resistant package that uses a foam tray

design that consumers are familiar with.

This machine is based on our leading automatic

packaging machine technology, and features a fully

automatic vacuum chamber with internal film sealing,

cutting and gas flushing. Belt conveyers transport the

package from the chamber into the integrated shrink

tunnel, shrinking the film to the contour of the item.

Uses centerfold film, which offers the

flexibility of changing item sizes and reducing

material cost. High speed production has never been so

EASY to achieve...regardless of the operator's skill

level.

Call us, or email

to discuss your food processing applications

The

ideal solution for processors seeking a

cost-effective automatic modified atmosphere packaging

system.

SPECIFICATIONS:

*300

mc/h - 12 hp -Pump *300

mc/h - 12 hp -Pump

*Maximum

film width - 16"

*Packs

Per Min. 9-14

*Footprint

10'4"x

4'6"x

5'4"h

*19

Selectable Programs

*Estimated

Ship Wt. 2300lbs.

*Package

size range - 6"x

8"x 4"h

10"x14"x2"h

*Power

-1 @ 208V/3ph

40Amp (sealer)

1 @ 208V/3ph 60Amp

(pump)

Specifications may change without

notice.

|

For

complete current or special pricing, call 800-759-3388,

or email us at: sales@atwmfg.com

We also offer a complete line of shrink wrap films, shrink wrap

accessories and shrink wrap supplies as well as high barrier

vacuum pouches for High Moisture Foods, Soups Dry Foods,

Powders, Spices, Seeds, Diagnostics and Industrial uses,

boilable vacuum pouches, chamber and non chamber vacuum

packaging machines, shrink tubing, impulse and constant heat

sealers, gift basket dome shrink bags, shrink bands, high speed

overwrap shrink machines, L-sealers, shrink wrap tunnels, heat

guns, non-stick PTFE sealing tapes, service kits and sealer

repair kits for almost any brand of heat sealing, vacuum

packaging or bag sealer equipment.

For complete current or special pricing,

call 800-759-3388 or email

HOME | ABOUT US

| CONTACT

US | GENERAL INFORMATION

© 2002 - 2022 ATW Manufacturing Company, Inc.

|

*300

mc/h - 12 hp -Pump

*300

mc/h - 12 hp -Pump  motorola

motorola